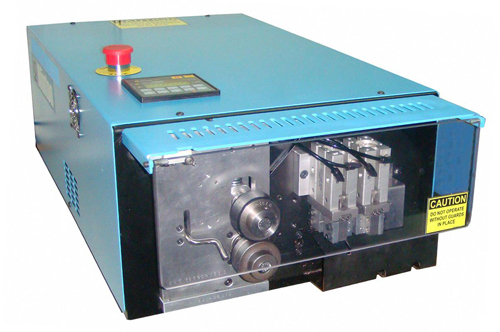

WJ600-CT AUTO CUTTING SYSTEM

Winton WJ600-CT半刚/半柔线缆下线机

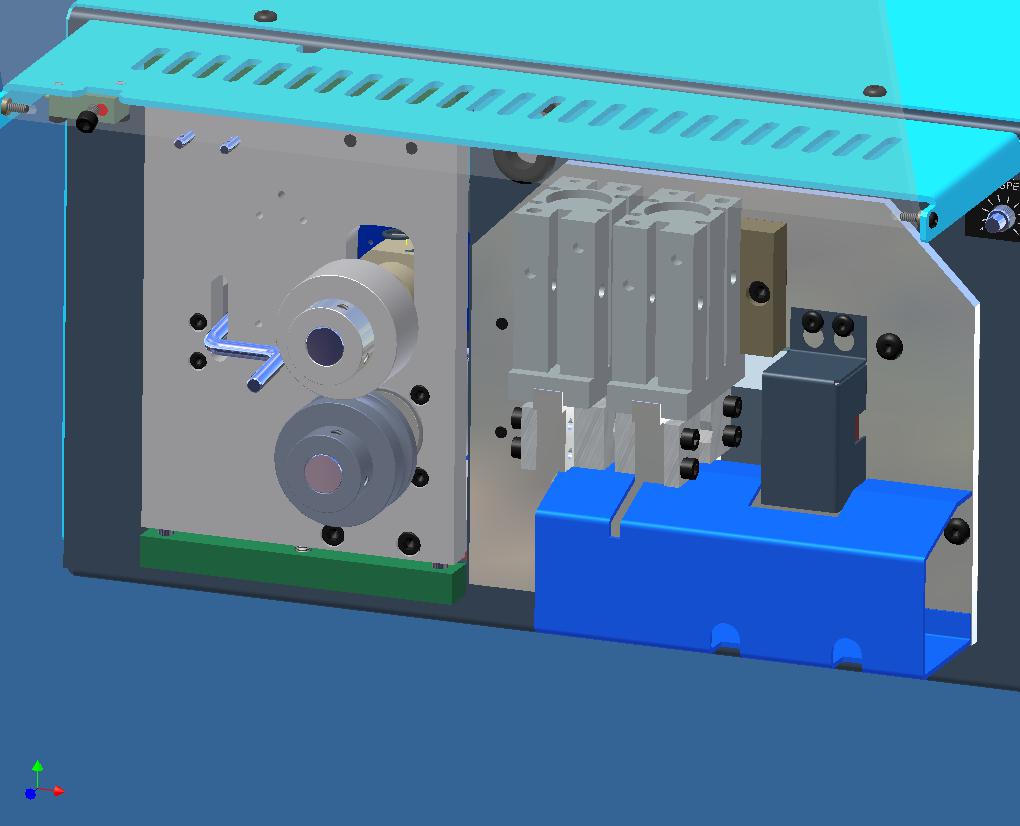

WJ600-CT是针对半刚性/半柔性/波纹电缆的全自动切割机,具有自动进料、可设定切割长度和切割数量等功能。该设备最大切割速度可达每分钟350mm,并且可在一秒内完成切割。专门配备2组气动线缆夹持爪,切割时紧紧夹住线缆,避免电缆晃动,确保切割端面平整,且不会在外导体表面留有划痕或外型损伤。

Standard Equipment

系统配置:

Microprocessor controlled

全自动微处理器控制,具有手动和自动进线功能

Closed loop feedback system used to feed material forward

进料机构自动反馈系统

2500 rpm saw used to cut material, dry cutting process

该设备使用的是高硬度合金刀片锯片转速达到2500 rpm,无需润滑剂

闭环反馈控制结合高精度进线长度测量机构,重复精度高达± 0.25 mm (0.010 in)

Programmable electric cross feed speed for cutting (1 thru 20)

电机驱动进刀/退刀,速度可调(1-20)

Programmable material feed rate (1 thru 5)

进料速度可调(1-5)

Programmable part cut length (inch/millimeters)

切割长度可设定(单位:英寸或毫米)

Programmable number of parts to cut

切割数量可设定

Programmable saw cut time

锯片切割时间可设定

(2) pneumatic grippers for material support while cross feed is cutting material

切割时2组气动线缆夹持爪夹紧线缆,减少电缆晃动,确保端面平整

Bench top mounted

体积小巧,可放置于桌面

Material low indicator switch used to detect end of material/bar stock

Material low indicator switch used to detect end of material/bar stock

缺料传感器,随时监测进料状态

Front interlocked guard (guard must be in position to operate saw)

前面板安全保护罩传感器(必须在关闭状态下设备才能运行)

(1) feed roll, customer specified size

一个通用进料主动轮

(1) High Speed Steel Saw Blade included

1片高速钢锯片

(1) set of gripper pads included, customer specified size

一组线缆夹持爪

(1) Set of 6’ Material Supports Included

一个6英寸线缆支撑导块

Features/Specifications - Standard:

性能特点/技术参数:

M600 Power Straightener (Ø6mm capacity)

M600 电动校直系统:

9 rolls in (1) vertical plane, assembly docks to WJ600-CT for rigid performance

9个垂直排列矫直轮,用于WJ600-CT前道矫直工序,适用于半刚/半柔性线缆

Powered roll dies synchronized to WJ600-CT

电力驱动,且可与WJ600-CT运行中实现同步

Adjustable top rolls for true alignment

可调节的上半部矫直轮,适用于不同线径和材质

All guards included

多重安全保护

Maximum material feed speed is 5 inches per second

最大校直速度可达每秒127mm

Additional 24V DC power supply for power feed

24VDC输出,可为放线机供电

Set of roll dies included

整套校直轮

Vertical feed in on bulk material required

可垂直进料,适用于大批量线缆校直

Bulk spool support included

放线缆盘支架

当前位置:产品详细

当前位置:产品详细